Locked up tight

Are we heading for a future in which it will be impossible for equipment owners and operators to maintain and repair their own machines?

Are we, as an industry, walking into a trap? A trap laid - deliberately or otherwise - by equipment manufacturers? Are we on the brink of a new era where we’re not just discouraged from maintaining our own equipment but actively prevented from doing so?

For years, construction equipment manufacturers - much like their counterparts in the automotive sector - have had us over a barrel when it comes to parts. “Failure to use genuine parts will invalidate your warranty,” they warn. It’s written into purchase agreements, lease deals, and operator manuals.

Setting aside the fact that these parts are for a machine that YOU own and YOU paid for, it has always irked me that manufacturers go out of their way to ensure you pay top dollar for replacement parts and consumables. You can shop around for the machine itself, comparing models from various brands and sources. But once they have you locked in, they slam the door shut to ensure any parts added to your machines are supplied by them, and them only.

I get it. If they’ve promised to keep your machine in tip-top order for the next four or five years, they can’t risk you shoehorning in a one-size-fits-all knock-off you picked up from a back alley in Kowloon.

Moreover, genuine OEM parts are generally manufactured specifically for the machine; they are of higher quality and produced to tighter tolerances. Aside from their price, they are better in nearly every conceivable way.

But as it stands today, you have a choice. You can opt for the OEM part or you can choose a spurious alternative. Yes, you might void your warranty, but that is your choice. Your prerogative.

However, we are entering an age where that choice may no longer be ours to make; an age where that prerogative is no longer an option.

Equipment manufacturers are already less than keen on any Tom, Dick, or Harry taking a spanner to one of their precious machines. Sealed units do keep oil and grease in, but they’re also pretty effective at keeping fitters and mechanics out. And this, potentially, is just the thin end of the wedge.

We’ve already seen how automotive manufacturers have made their systems so complex, so inaccessible, that car owners often have little choice but to return to the local dealer every time something needs maintaining or repairing: brake pads, headlight bulbs, windscreen wiper blades. Yep, back to the dealer.

Simultaneously, both car and construction equipment manufacturers have installed advanced electronic systems whose sole aim – apparently - is to guilt-trip you into another call to the local dealer.

Back in the day, I went years without checking tyre pressures or oil levels. Now, my wife’s car does all that for me, and it bleeps and flashes until I’ve made the necessary adjustments. It does so with service intervals too; a little red light on the dash that effectively means, “Take me back whence I came... and bring your chequebook.”

There was a time when maintaining your machine was a rite of passage. Operators didn’t just run machines. They knew them. Understood them. There was pride in being self-sufficient. Walk onto a site 20 or 30 years ago, and you’d see operators with grease guns in hand and toolboxes in the cab.

That kind of hands-on ownership has been slowly eroded. Now, a flashing light on a touchscreen has replaced gut instinct, and a service rep has replaced the fitter.

This situation could get much, much worse.

How much time, I wonder, does the average Tesla owner spend with their head under the bonnet? Do they fix and maintain? Do they tinker? Can they?

That, potentially, is our future. A shiny new machine that you cannot maintain or repair without costly outside help.

Now stir into the mix the advent of telematics. Telematics systems are tracking not only engine hours and fuel burn, but also idling time, operator behaviour, and GPS location.

That information is beamed back to the manufacturer or dealer, creating a one-way mirror. They see everything. You see only what they let you see. And increasingly, that data isn’t just used to monitor performance. It’s used to market services, push predictive maintenance, and upsell parts.

Imagine a world where your machine phones home, and instead of you deciding whether it needs servicing, the dealer shows up uninvited - invoice in hand - because the system has already “pre-approved” the work.

There is an irony here. Equipment manufacturers like Komatsu can produce a “power agnostic” mining truck that allows the owner to switch from a diesel engine to a battery power pack, a trolley electric system, or even to a hydrogen fuel cell when such technology becomes commercially available. Modularity is at our fingertips. It is surely not beyond the ingenuity of design engineers to make machines in which key elements - everything from oil filters to entire engines - could just be slotted in and out like additional storage on a computer’s mother board.

One of the key ways we might minimise our industry’s environmental impact is to break the cycle of running machines for three or four years and then replacing them with new ones; a process that carries a significant carbon footprint.

If we could hang onto those machines for five years instead of three, or ten years instead of five, we could make a substantial contribution to the industry’s sustainability credentials.

But for that to truly work, equipment owners need to be able to maintain their machines, to repair them, and yes, even to tinker with them.

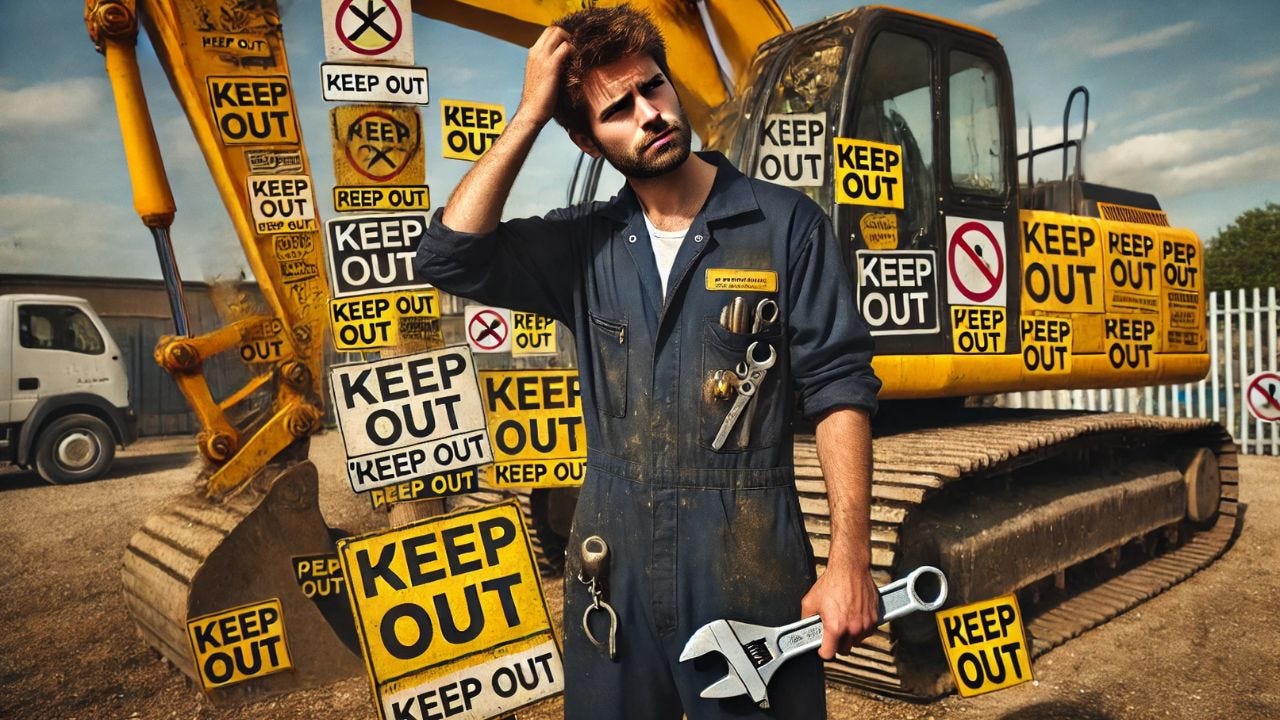

We are currently on a path toward a future where you might one day open the hood of your excavator or dozer, only to find a large sign reading “Keep Out.” When that day arrives, you will be able to do nothing with that machine – YOUR MACHINE - without the permission of the manufacturer and the intervention of the local dealer.

Such a future might safeguard your warranty. But is that really a future we want?