Optional once more

In an age of creeping autonomy, will machine cabs once again become optional?

During a previous visit to the Volvo Construction Equipment headquarters in Eskilstuna, Sweden, I visited the nearby Munktell Museum where they have a collection of vintage construction and agricultural equipment.

One machine I remember vividly was an early ADT, probably from the 1960s. I sat in it. The seat was basically a plank of wood, and the steering wheel looked like it had been salvaged from an early steam ship. Worse still, the engine was located right behind the operator’s head. If the fumes didn’t get you, the noise definitely would.

Mind you, at least it had a cab. Early dozers were open to the elements - If it was hot, the operator baked. If it rained, the operator was wet.

Even the early mini excavators that made landfall in the UK in the 1980s arrived with canopies. If the rain fell straight down, you were protected. If there was even a slight breeze, you were soaked.

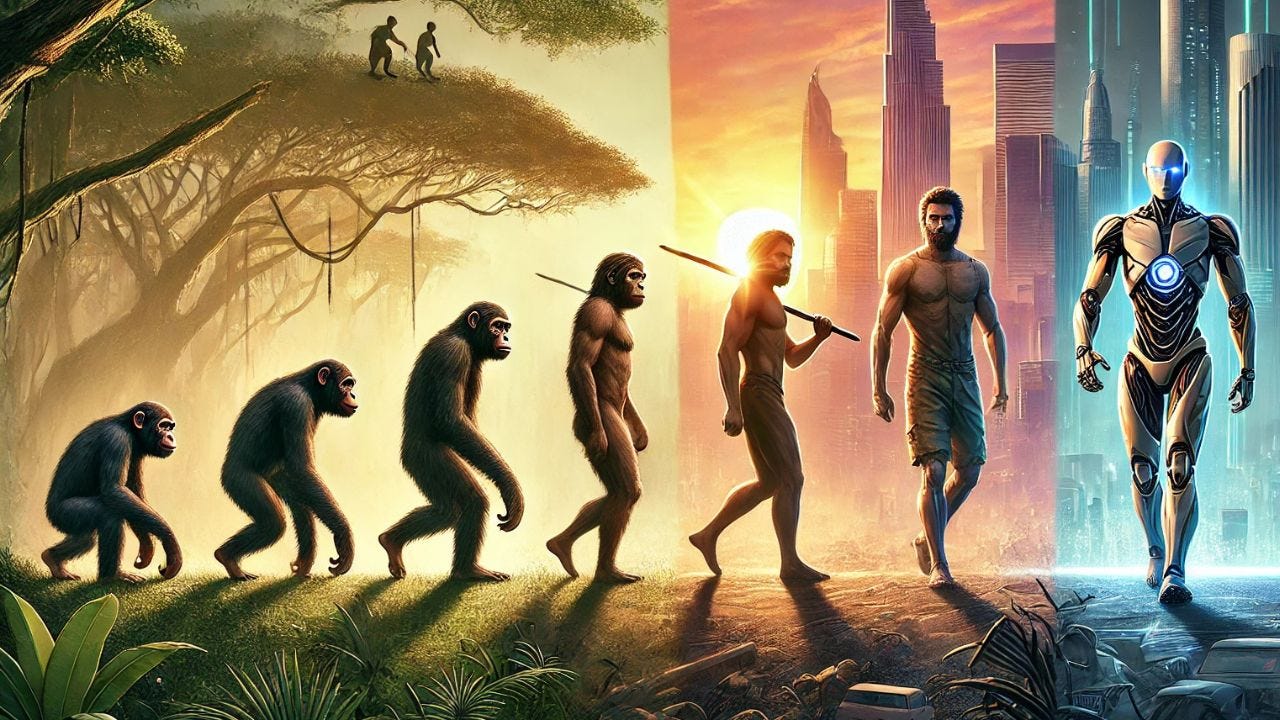

Since the earliest days of mechanised plant and equipment, operators have sat behind the levers of machines that were often rudimentary, offering little more than a basic platform to get the job done. But as the industry evolved, so too did the machines.

As technology advanced and safety regulations became more stringent, manufacturers began to recognise the need to protect the operators, not just the machinery itself. The first major change was the introduction of enclosed cabs, designed to shield workers from falling debris, extreme weather, and noise. By the mid-to-late 20th century, the operator’s cab had transformed into a fully enclosed, air-conditioned haven with features designed for comfort as much as safety. No longer was the operator exposed to the elements; they were now shielded in a comfortable, controlled environment, reducing fatigue and stress during long work hours.

Machines began to include advanced features like Bluetooth connectivity, touchscreens, and integrated communication systems, making it easier for operators to stay in touch with other team members. The seats were engineered with ergonomic considerations; adjustable, cushioned, and even equipped with suspension to reduce the impact of vibration and rough terrain. These upgrades didn’t just improve comfort; they enhanced productivity and efficiency, allowing workers to focus on the task at hand rather than the discomfort of their environment.

The evolution from bare-bones machines to state-of-the-art equipment was not just about the machines getting more sophisticated. It was a clear response to the changing needs of workers. The industry began to prioritise operator comfort and safety, realising that a well-cared-for worker is a more productive and accurate worker. By improving the design of the cab, the controls, and the comfort of the operator, manufacturers ensured that skilled labour could perform at a higher level, with reduced risk of injury and burnout.

But what of the future?

After more than 100 years of designing machines with the operator in mind, could we be heading toward an era where the very features that have become standard - the seat, the joysticks, even the cab - might no longer be necessary?

This question arises as the construction and demolition industry pivots toward autonomy. With labour shortages continuing to plague the sector and sustainability goals pushing the industry toward zero-emissions, autonomous machines are emerging as a potential solution. These machines don’t require human operators in the traditional sense. They can work around the clock without needing breaks, and they don't have the same risk of human error. As a result, some manufacturers are exploring the possibility of eliminating the need for human-facing features altogether.

In one sense, the move toward autonomous equipment is a logical progression. It promises to address labour shortages, improve safety, and meet the industry’s growing sustainability demands. However, it also raises a paradox: after spending over a century designing machines to enhance the operator’s comfort and safety, could we soon be looking at machines where the human-facing features are rendered obsolete?

If autonomous technology continues to progress, and machines can be controlled remotely or function without an operator inside, what will become of the ergonomic, comfort-focused designs we've come to expect? Would traditional equipment be retrofitted to accommodate automation, removing the features that were once designed to protect the operator? Alternatively, could we see an industry where these features become optional, and the human operator is relegated to a supervisory or monitoring role, overseeing a fleet of autonomous machines from a central control station?

Looking ahead, the future of construction and demolition machinery could look vastly different from what we know today. On a typical job site, instead of a fleet of operators working inside their heavy-duty equipment, we might see a variety of machines working autonomously, with a small number of human operators overseeing them remotely. The traditional image of the operator sitting behind the levers could soon be replaced by a control centre, where workers monitor and adjust the work of several machines at once.

The question, then, becomes: How does the industry reconcile these two forces? The move toward autonomy is inevitable, driven by the need for efficiency, safety, and sustainability. Yet, the human-facing design elements of machinery are deeply entrenched in the culture of construction and demolition. Will we find a balance, where machines continue to offer both autonomous functionality and optional operator comfort, or will the days of the human-driven machine, with its seat and joysticks, eventually become a thing of the past?

And might we just go full circle. Those early mini excavators that came with canopies offered cabs as an option. If autonomy truly takes hold, those cabs might yet become optional again. And those operators that were once an afterthought? They could become a distant memory.